Abstract

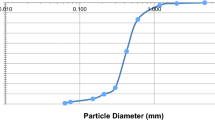

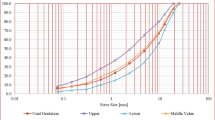

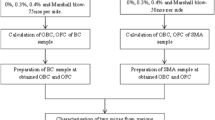

Agricultural waste materials are potentially dependable and affordable road construction materials that help to develop sustainable pavements, reducing nuisance waste and minimizing construction costs. To determine the suitability of coconut fiber ash (CFA) for use as a filler in asphaltic concrete, this study evaluates the effects of CFA as a filler on the properties of asphaltic concrete. According to ASTM requirements, tests to ascertain the physical and chemical properties of the bitumen, filler, and fine and coarse aggregate were conducted. Marshall specimens were created using varying percentages of 5%, 10%, 15%, 20%, and 25% of coconut fiber ash. To assess each sample’s effectiveness, six replacement rates of 5.0 to 7.5% at an interval of 0.5% by weight were used to determine the optimum bitumen content (OBC), and volumetric characteristics like flow test, stability, density, and air void in mineral aggregates were studied. It was observed that 15% of CFA filler replacement achieved the best values of OBC at 6.3%, maximum stability at 14.4 KN, flow at 3.8 mm, void filled with bitumen (VFB) at 84.9%, bulk density at 2.55 g/cm3, air void at 4.3%, and lastly marshal quotient value was 3.8 KN/mm which met all the requirement of the standard specification for medium-traffic roads in asphalt mixture. To ensure the optimum performance of the CFA-modified asphalt mixtures, a 15% CFA is recommended.

Similar content being viewed by others

References

Bieliatynskyi A, Yang S, Krayushkina K, Shao M, Ta M (2022) Study of the possibility of using phosphorous slags in road construction. Eng Sci Technol Int J 36:101262

Choudhary J, Kumar B, Gupta A (2020) Utilization of solid waste materials as alternative fillers in asphalt mixes: a review. Constr Build Mater 234:117271

Tam VW, Soomro M, Evangelista ACJ (2018) A review of recycled aggregate in concrete applications (2000–2017). Constr Build Mater 172:272–292

Greer F, Thaneya AB, Apte JS, Horvath A (2022) Pavement resurfacing and supply chains are significant contributors to PM2. 5 exposure from road transportation: evidence from the San Francisco Bay Area. Environ Res Lett 17(12):124014

Praticò FG, Giunta M, Mistretta M, Gulotta TM (2020) Energy and environmental life cycle assessment of sustainable pavement materials and technologies for urban roads. Sustainability 12(2):704

Milad A, Babalghaith AM, Al-Sabaeei AM, Dulaimi A, Ali A, Reddy SS, Yusoff NIM (2022) A comparative review of hot and warm mix asphalt technologies from environmental and economic perspectives: towards a sustainable asphalt pavement. Int J Environ Res Public Health 19(22):14863

Segui P, Safhi AEM, Amrani M, Benzaazoua M (2023) Mining wastes as road construction material: a review. Minerals 13(1):90

Soni A, Das PK, Hashmi AW, Yusuf M, Kamyab H, Chelliapan S (2022) Challenges and opportunities of utilizing municipal solid waste as alternative building materials for sustainable development goals: a review. Sustain Chem Pharm 27:100706

Kifile D, Getu N, Mesfin A, Yifru W, Sewunet A (2023) Evaluation of maize cob ash as filler in hot-mix asphalt concrete production. Int J Pavement Res Technol 16(3):592–605

Adeboje AO, Bankole SO, Apata AC, Olawuyi OA, Busari AA (2022) Modification of lateritic soil with selected agricultural waste materials for sustainable road pavement construction. Int J Pavement Res Technol 15(6):1327–1339

Perey R, Benn S, Agarwal R, Edwards M (2018) The place of waste: changing business value for the circular economy. Bus Strateg Environ 27(5):631–642

Nwakaire CM, Yap SP, Onn CC, Yuen CW, Ibrahim HA (2020) Utilization of recycled concrete aggregates for sustainable highway pavement applications; a review. Constr Build Mater 235:117444

Dalhat MA, Osman SA, Mu’azu ND, Alagha O (2022) Utilization of oil sludge as a rejuvenator in hot-mix-asphalt containing reclaimed asphalt concrete. Constr Build Mater 338:127483

Upadhya A, Thakur MS, Sihag P, Kumar R, Kumar S, Afeeza A, Saleel CA (2023) Modelling and prediction of binder content using the latest intelligent machine learning algorithms in carbon fiber reinforced asphalt concrete. Alex Eng J 65:131–149

Osuya DO, Mohammed H (2017) Evaluation of sawdust ash as a partial replacement for mineral filler in asphaltic concrete. IFE J Sci 19(2):431–440

Oguntayo D, Ogundipe O, Aladegboye O, Ogunkunbi G, Babatunde Y, Aransiola O (2023) Performance evaluation of hospital waste ash-modified asphalt mixtures. Adv Civ Eng 2023:1–7

Choudhary J, Kumar B, Gupta A (2018) Application of waste materials as fillers in bituminous mixes. Waste Manag 78:417–425

Robert UW, Etuk SE, Agbasi OE, Umoren GP, Inyang NJ (2021) Investigation of thermophysical and mechanical properties of board produced from coconut (Cocos nucifera) leaflet. Environ Technol Innov 24:101869

Tomar R, Jain RK, Kostha MK (2013) Effects of fillers on bituminous paving mixes. Int J Eng Res Sci Technol 2(4):2319–5991

Mistry R, Roy TK (2021) Performance evaluation of bituminous mix and mastic containing rice husk ash and fly ash as filler. Constr Build Mater 268:121187

Fayissa B, Gudina O, Yigezu B (2021) Application of sawdust ash as filler material in asphalt concrete production. Ann Fac Eng Hunedoara 19(1):167–172

Jia Y, Yang Y, Zhou T, Gao Y, Wang S, Wei Z (2022) Stiffening effect of filler on asphalt mastic composite: a new insight based on nearest surface function. Constr Build Mater 344:128177

EN 1426:2015 (2015) Bitumen and bituminous binders Determination of needle penetration. British Standard Institute (BSI), London, UK

IS:1203 (1978) Methods for testing tar and bituminous materials: determination of penetration. Bureau of Indian Standard, New Delhi, India

ASTM D6 (2018) Standard test method for loss on heating of oil and asphaltic compounds. ASTM International, West Conshohocken, PA, USA

IS:1208 (1978) Methods for testing tar and bituminous materials: determination of ductility. Bureau of Indian Standard, New Delhi, India

ASTM D113-99 (2010) Standard test method for ductility of bituminous materials. ASTM International, West Conshohocken, PA, USA

IS:1205 (1978) Methods for testing tar and bituminous materials: determination of softening point. Bureau of Indian Standard, New Delhi, India

ASTM D36-06 (2010) Standard test method for softening point of bitumen (ring-and-ball apparatus). ASTM International, West Conshohocken, PA, USA

ASTM D70-18a (2021) Standard test method for density of semi-solid bituminous materials (pycnometer method). ASTM International, West Conshohocken, PA, USA

IS:1206 (Part II) (1978) Methods for testing tar and bituminous materials: determination of viscosity. Bureau of Indian Standard, New Delhi, India

ASTM D2171-07 (2010) Standard test method for viscosity of asphalts by vacuum capillary viscometer. ASTM International, West Conshohocken, PA, USA

EN ISO2592:2017 Petroleum and related products—determination of flash and fire points—Cleveland open cup method (ISO 2592:2017)

ASTM D92 (2018) Standard test method for flash and fire points by Cleveland open cup tester. ASTM International, West Conshohocken, PA, USA

ASTM C127-15 (2016) Standard test method for relative density (specific gravity) and absorption of coarse aggregates. ASTM International, West Conshohocken, PA, USA

ASTM D5874–16 (2016) Standard test methods for determination of the impact value (IV) of a soil. ASTM International, West Conshohocken, PA, USA

ASTM C131-06 (2010) Standard test method for resistance to degradation of small-size coarse aggregate by abrasion and impact in the Los Angeles machine. ASTM International, West Conshohocken, PA, USA

ASTM D4719 (2020) Standard test methods for prebored pressuremeter testing in soils. ASTM International, West Conshohocken, PA, USA

ASTM-D1559 (1989) Test method for resistance of plastic flow of bituminous mixtures using marshal apparatuzs (Withdrawn 1998). ASTM International, West Conshohocken, PA, USA

AASHTO T 245 (2015) Standard method of test for resistance to plastic flow of asphalt mixtures using marshall apparatus. American Association of State Highway and Transportation Officials (AASHTO), Washington, DC, USA

Zainudin MZM, Khairuddin FH, Ng CP, Osmi C, Khadijah S, Misnon N, Murniati S (2016) Effect of sugarcane bagasse ash as filler in hot mix asphalt. Mater Sci Forum 846:683–689

Gunalaan V (2013) Performance on coal bottom Ash in hot mix asphalt. IJRET 2319–1163:24–33

Sebnem S, Mehmet S, Nihat M, Sercan S, Serdal T (2013) Evaluation of rice husk ash as filler in hot mix asphalt concrete. Constr Build Mater 48:390–397

Mistry R, Roy TK (2020) Predicting Marshall stability and flow of bituminous mix containing waste fillers by the adaptive neuro-fuzzy inference system. Rev Constr 19(2):209–219

Siswanto H, Supriyanto B, Pranoto, Chandra PR, and Hakim AR (2017) Marshall properties of asphalt concrete using crumb rubber modified of motorcycle tire waste. In: AIP conference proceedings, vol 1887, pp 020039

Acknowledgements

The authors appreciate the Federal University of Technology, Akure, and Landmark University Omu-Aran, Kwara State, for the laboratory support throughout this research work.

Funding

No funds, grants, or financial support were received for conducting this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest among authors in this manuscript.

Ethical approval

This article does not involve any research involving human participants or animals conducted by any of the authors.

Informed consent

For this particular study, formal consent is not necessary.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Asebiomo, O.J., Aderinola, O.S., Ejigboye, P. et al. Performance evaluation of coconut fiber ash as mineral filler in asphalt mixture. Innov. Infrastruct. Solut. 9, 141 (2024). https://doi.org/10.1007/s41062-024-01449-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1007/s41062-024-01449-x